Services Offered

AGF Defcom Inc. provides advanced manufacturing solutions for industries such as automotive, tool and die, oil and gas, aerospace, and defense. Since 2016, the company has continued to expand its capabilities by investing in leading-edge technology and equipment.

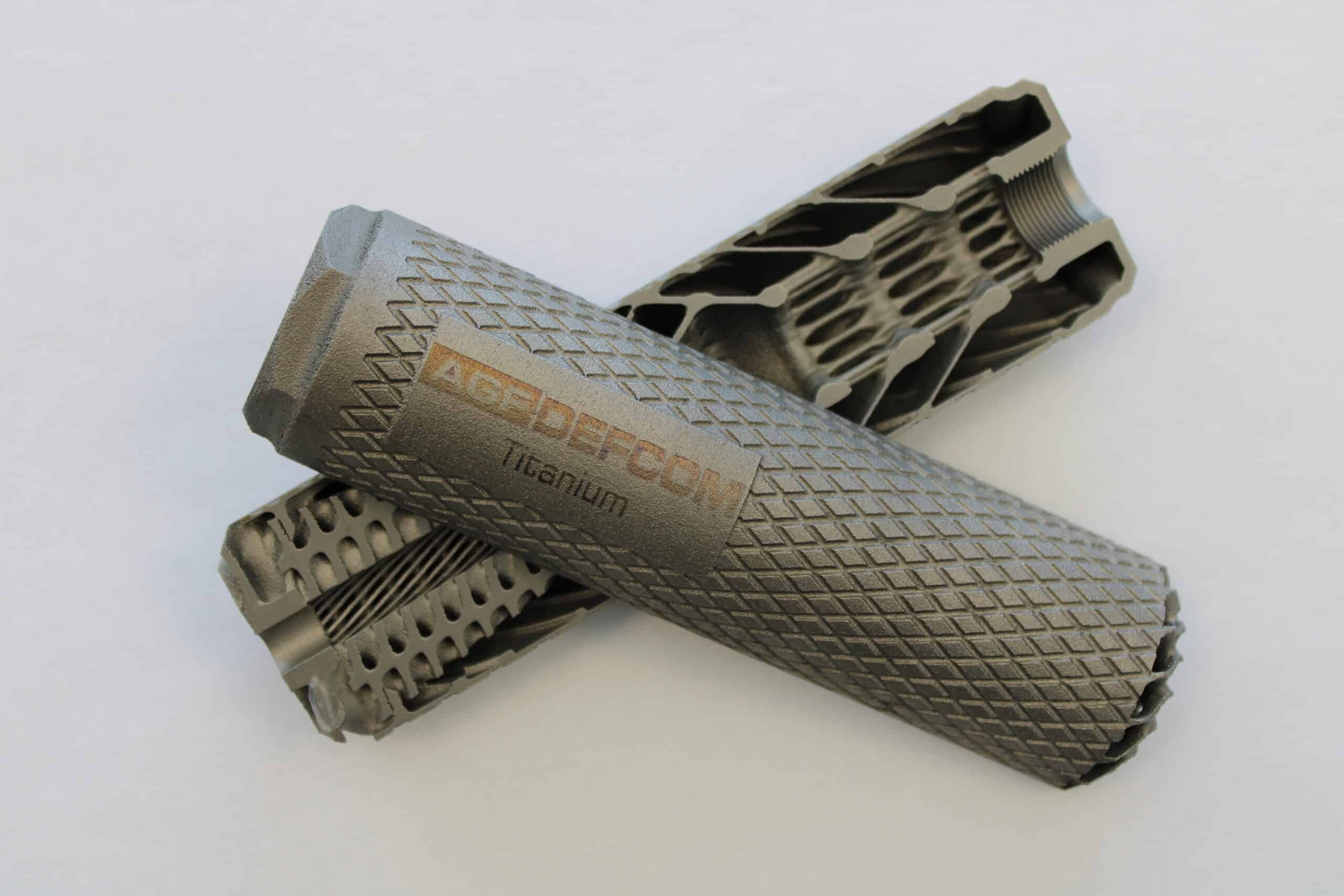

A key area of growth has been Additive Manufacturing, featuring a fleet of 20+ DLMS printers supported by a wide range of secondary processes. Beyond additive printing, services include material testing, heat treating, post machining, and laser engraving—allowing customers to rely on a single, fully integrated manufacturing partner.

Each part is subjected to rigorous quality assurance inspections to ensure it meets all customer specifications and performance requirements.

“We are a One Stop Shop, with the ability to go from prototype to full scale production”

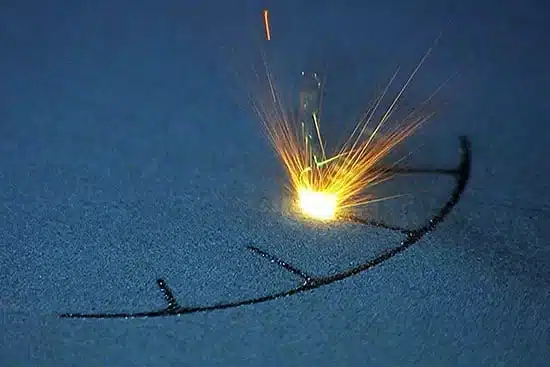

DLMS 3D Printing (Production & Prototyping)

Whether it’s one part or thousands of parts, AGF Defcom can handle your Additive Manufacturing needs. Through the use of our custom printing parameters, our engineers can work with you to get the best possible parts based on your material and needs. We utilize 20+ EOS DLMS Printers to handle even the largest orders.

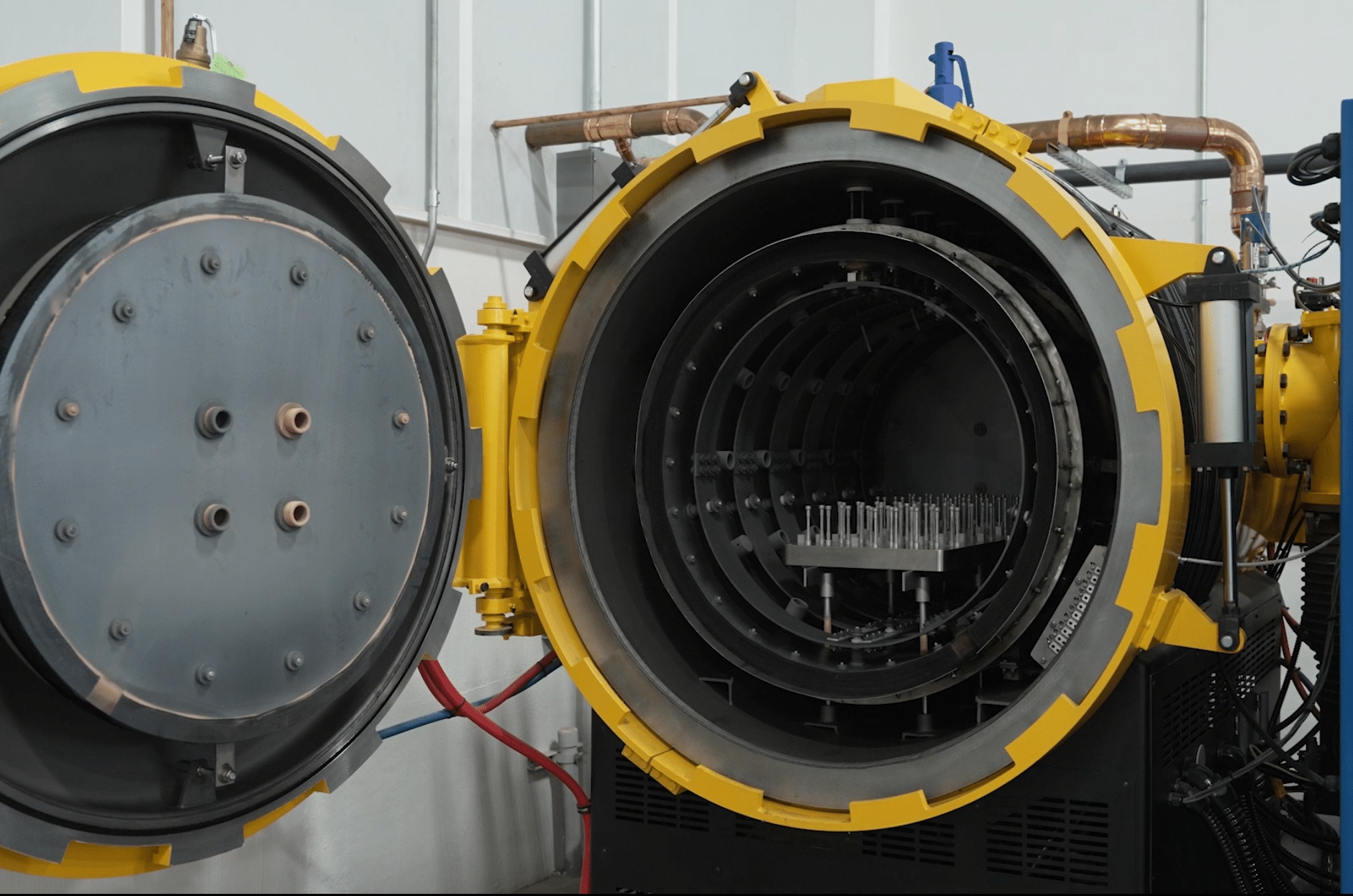

Heat Treatment

Our Vacuum Furnaces ensure that you are getting the best end product possible. We offer different cycles specific to the material being worked with to ensure your product is in its most durable state. Under a vacuum furnace you get all of the benefits of heat treating without risk of oxidation or contamination through oil quenches. Cycles can be customized based on your material and needs to achieve the requested final result.

Post-Machining Services

Our facility is equipped with a dozen lathes dedicated to post-processing, ensuring every part meets exact specifications. We use custom tooling and part-specific programming to deliver precision finishing, tailored to your unique requirements.

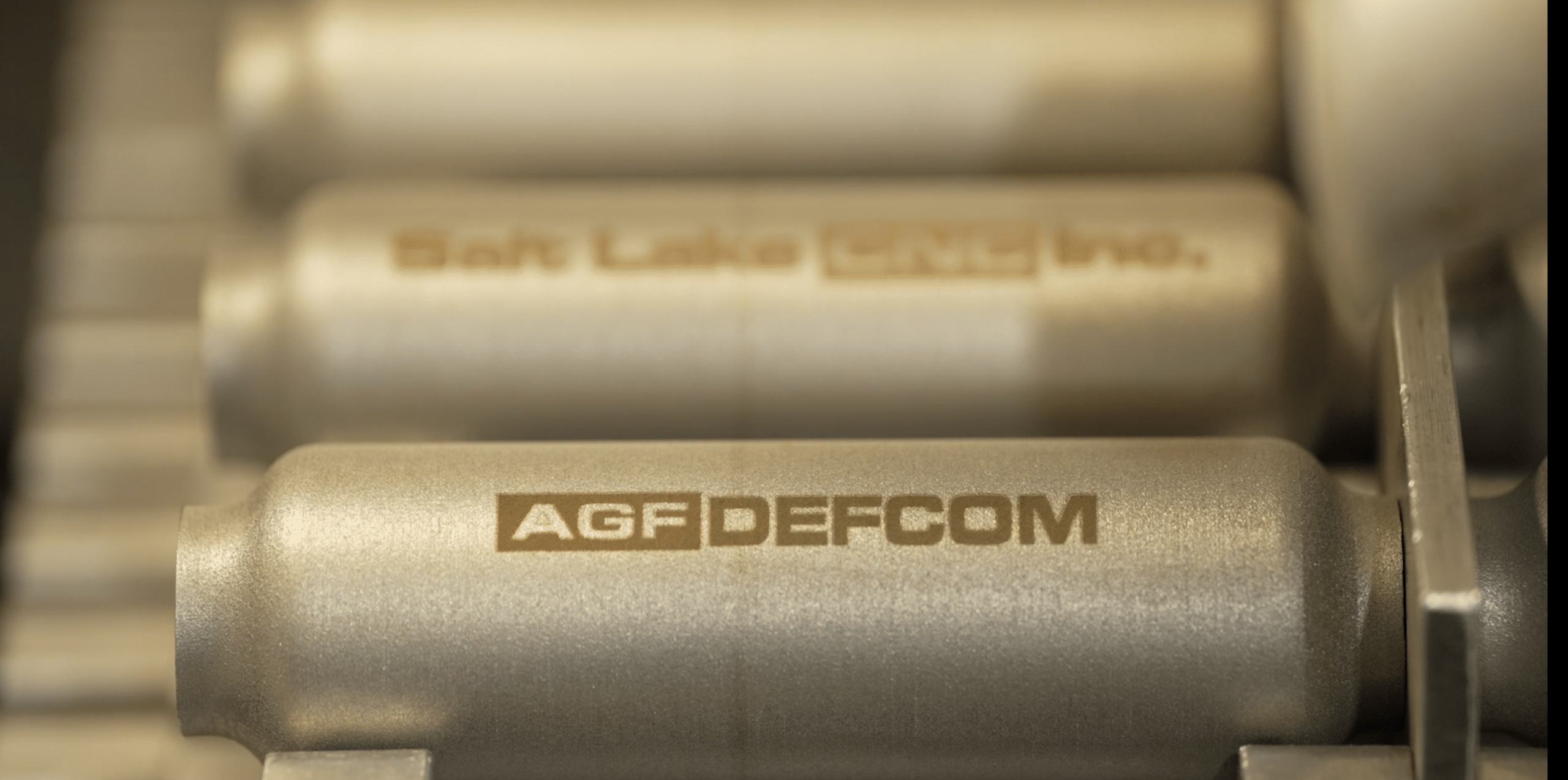

Precision Laser Engraving

We provide accurate, permanent markings for your parts using advanced laser technology. From serial numbers to custom logos, our process delivers crisp detail on flat or cylindrical surfaces with a finish that lasts.

Quality Assurance

AGF Defcom is committed to providing innovative solutions, product excellence, value and customer satisfaction utilizing continuous improvement principles, teamwork and employee development. Our Quality Assurance deparment ensures evey part is up to the customers standard!

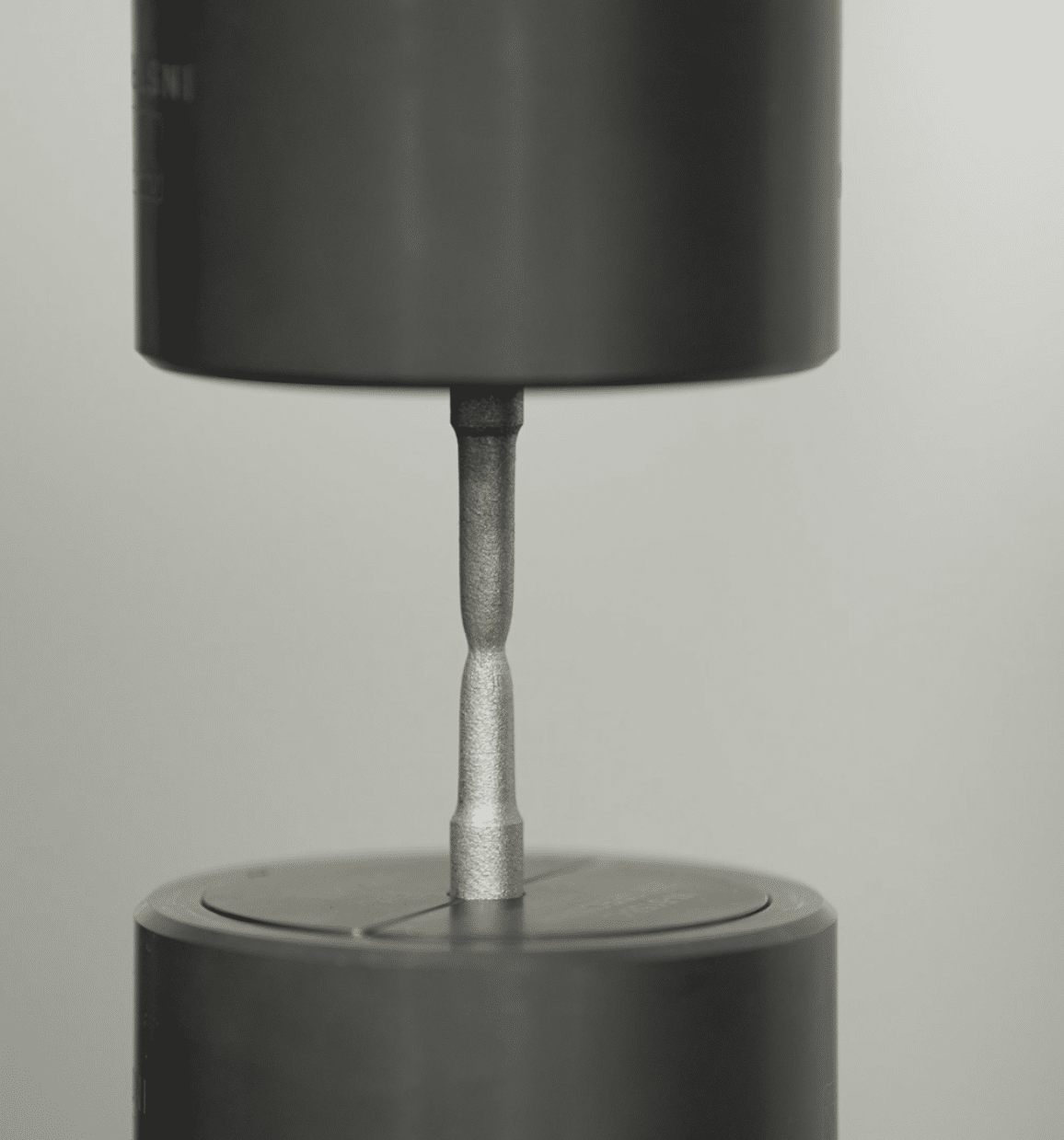

Material Testing

We perform rigorous tensile, Hardness, and Density testing to ensure material strength and reliability. Each build includes one tensile bar and Harness/Density Cube per laser. All testing is conducted on site in compliance with ISO 9001 standards, guaranteeing consistency, quality, and performance.

Laser Power Calibration & Verification

Our facility ensures peak performance and precision through laser power calibration and routine checks. Each laser is tested and adjusted to maintain consistent energy output, guaranteeing accuracy in every build.

Materials Available

Ti-6Al-4V (Ti64)

Lightweight, high-strength titanium alloy with excellent corrosion resistance and biocompatibility. Ideal for aerospace, medical, and performance-critical applications requiring complex geometries.

Inconel® 625

Nickel superalloy known for outstanding corrosion and oxidation resistance. Well suited for harsh chemical, marine, and high-temperature environments with excellent additive manufacturability.

Inconel® 718

High-strength nickel superalloy engineered for extreme heat and stress. Commonly used in aerospace, energy, and propulsion components requiring superior fatigue and creep resistance.

17-4 PH Stainless Steel

Versatile precipitation-hardened stainless steel offering a strong balance of strength, durability, and corrosion resistance. Ideal for industrial, tooling, and general structural applications.

Have another Material in Mind – Reach out today